What is physical refining of edible oil?

Physical refining of edible oil is also called steam distillation deacidification, which is according to the characteristics of volatile difference between triglycerides and free fatty acids (under vacuum condition), in high vacuum (0.6 kPa) atmospheric pressure and high temperature (240 ~ 260 ℃) to remove free fatty acids and other volatile substances from oil by water vapor distillation.

The boiling point of different fatty acids under different conditions:

| Fatty acid | No water vapor (atmospheric pressure) | Fatty acid : water vapor | |

| Atmospheric pressure (1 : 2.5) | 20kPa (1 : 1) | ||

| Lauric acid | 301 | 191 | 167 |

| myristic acid | 330 | 211 | 173 |

| palmitic acid | 340-356 | 224 | 211 |

| stearic acid | 360-383 | 243 | 223 |

| oleic acid | -- | 239 | 220 |

Physical refining of edible oil is particularly suitable for low-gum tropical oil seeds, such as palm and coconut, etc, and for refining animal fats.

In edible oil physical refining process, steam distillation can not only remove acid, but also can achieve removing solvent in leaching oil, deodorized, detoxified (organochlorine in rice bran oil and some cyclic hydrocarbons and other toxic substances) and partially decolorized.

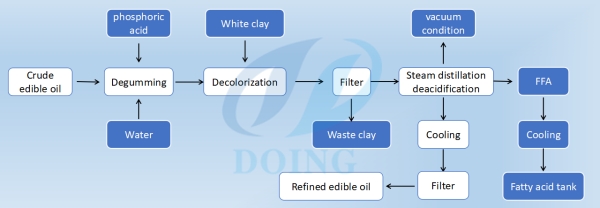

Edible oil physical refining process

Edible oil physical refining process

The crude oil quality requirements before physical deacidification:

The quality of crude edible oil and its pretreatment quality are the preconditions of physical refining of edible oil. Non-hydrophilic phospholipids in crude edible oil are mostly carriers of metal ions such as calcium, magnesium and iron, which can lead to a deeper color, less transparency, lower flavor and stability, and even make the deacidification and deodorization process fail. Therefore, in the edible oil physical refining process, the crude edible oil must be pretreated degumming and decoloring.

The key point of physical refining of edible oil:

1. Steam distillation deacidification(continuous)

Temperature: 250~270℃

Pressure: 0.25~0.40kPa(2-3mmHg)

Time: 80-100min

The direct steam consumption: 1%-4%G0; (0.1-0.2MPa)

2. Cooling and filter

60-70℃

The characteristics of physical refining of edible oil:

1. Less consumption of auxiliary materials, no sewage;

2. Simple process, less equipment, low operating cost;

3. High refining rate;

4. Fined edible oil is of high quality;

5. Physical refining of edible oil has some limitations;

6. After physical refining of edible oil, if the oil color is deep, it is difficult to remove.

Physical refining of edible oil and chemical refining of edible oil both have their own advantages. Henan Doing Company is a professional manufacturer of edible oil refinery machine. If you have any question, our engineer will explain to you. Welcome to write down your message!

Leave a message

If you wanna to get more details about What is physical refining of edible oil?, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

10tpd cooking oil refining plant is under installation in Kenya

10tpd cooking oil refining plant is under installation in Kenya

-

Henan Glory to supply 1tpd edible oil refinery machine to Guinea client

Henan Glory to supply 1tpd edible oil refinery machine to Guinea client

-

Henan Glory secures central Africa order for small edible oil refinery plant (200kg/d)

Henan Glory secures central Africa order for small edible oil refinery plant (200kg/d)

-

Nigeria: 50tpd palm oil refining & 30tpd fractionation equipment deal signed

Nigeria: 50tpd palm oil refining & 30tpd fractionation equipment deal signed

-

Burundi client boosts oil quality with 5tpd palm oil fractionation machine from Henan Glory

Burundi client boosts oil quality with 5tpd palm oil fractionation machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria