How does a crude edible oil refinery plant work?

Edible oil refinery plant is mainly to process crude vegetable oil into refined edible oil. But do you know how a crude edible oil refinery plant works? A crude edible oil refinery plant has five steps to refine the crude vegetable oil: Degumming, Deacidification, Decolorization, Deodorization and dewaxing or fractionation. But different edible oil refinery plant has different working process.

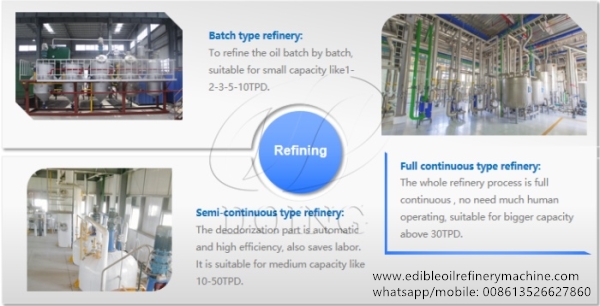

Three types of edible oil refinery plant we can provide

Three types of edible oil refinery plant we can provide

There are three types of edible oil refinery plant: 1-20tpd batch type edible oil refinery plant, 10-50tpd semi continuous edible oil refinery plant and 50-2000tpd fully continuous edible oil refinery plant. They use different equipment, so have different working process. The biggest difference is in degumming and deodorization sections.

The difference of degumming section:

In batch type and semi-continuous edible oil refinery plant, degumming tanks are used, where the crude oil reacts with alkali. At the same time, little hot water and phosphoric acid is added to move the gum.

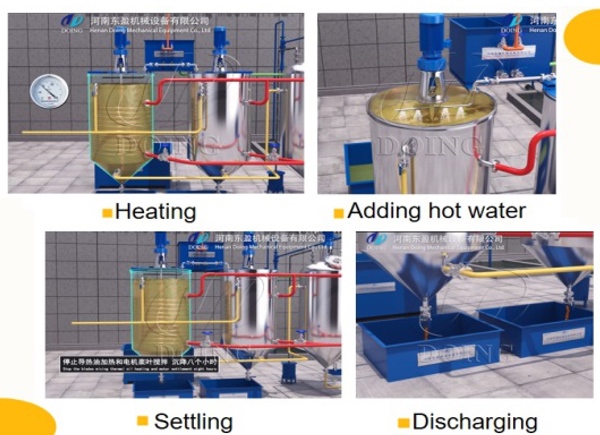

The degumming process in batch type and semi-continuous edible oil refinery plant

The degumming process in batch type and semi-continuous edible oil refinery plant

After reaction, it need natural sinking about 4-6 hours. Then the gum and nigre are separated from the oil. Several tans are used alternately, because the sinking time is a little long.

In the continuous edible oil refinery plant, centrifugal mixer and centrifugal are used. Crude oil, lye, hot water and phosphoric acid are reacted in the centrifugal mixer. Then the centrifugal will separate the water and nigre from the oil. The whole process can finished continuously.

The centrifugal mixer used in continuous edible oil refinery plant

The centrifugal mixer used in continuous edible oil refinery plant

The difference of deodorization section:

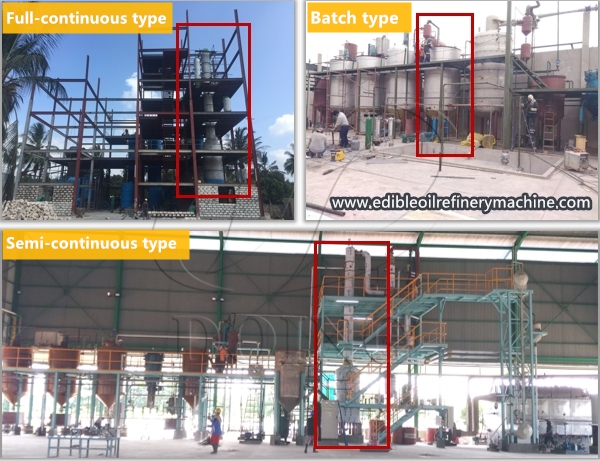

In batch type edible oil refinery plant, the deodorization pot is used. It only can remove the smell of the oil by hot steam. In semi-continuous and continuous edible oil refinery plant, the deodorization and deacidification tower is used. It uses to the physical oil refining method to move the acid and smell at the same time.

Different deodorization equipment in three type of edible oil refinery plant

Different deodorization equipment in three type of edible oil refinery plant

And other sections of the edible oil refinery plant are same. If you want to learn more about edible oil refinery process, you can read this article. (Related reading: Edible oil refining process flow chart introduction)

What's more, different kinds of crude edible oil need different refining process. For example, sunflower oil refinery plant should be contains dewaxing section and palm oil refinery plant can add fractionation section.

Doing Company is very professional edible oil refinery plant manufacturer, and we can design for you according to your needs. Welcome to leave a message.

PREV:Edible oil refinery equipment maintenance rules

NEXT:Palm kernel oil refinery plant working principle with diagram

Leave a message

If you wanna to get more details about How does a crude edible oil refinery plant work?, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

-

Rwanda customer ordered 5TPD palm oil fractionation machine from Henan Glory Company

Rwanda customer ordered 5TPD palm oil fractionation machine from Henan Glory Company