We have been specialized in canola oil extraction plant since 1967. We can offer whole line of canola oil extraction plant with turnkey service, capacity from 10 to 6000TPD . For special capacity, our engineers can help you design and install canola oil extraction plant according to your real conditions.

Canola oil extraction plant starts with rapeseed, with oil content 40%, more or less. Same with other common oilseeds, there're four main sections of canola oil extraction plant, including prepressing/pressing/pretreatment section, solvent extraction section, refinery section and dewaxing/winterization section.

►Pressing/Prepressing of canola oil extraction plant:

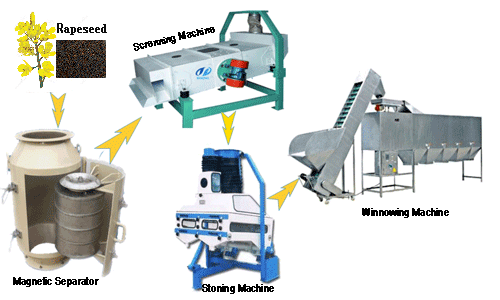

Rapeseed → cleaning → softening → flaking → cooking → pressing → pressed canola oil + pressed cake

1. Cleaning :

Cleaning section contains magnetic selector, stoning machine, etc. The main function of cleaning is to remove mechanical impurities in rapeseed.

2. Softening:

Softening is to adjust the temperature and moisture of rapeseed with steam.

3. Flaking :

Flaking uniforms oil seeds to thin cake, which benefits oil pressing and extraction.

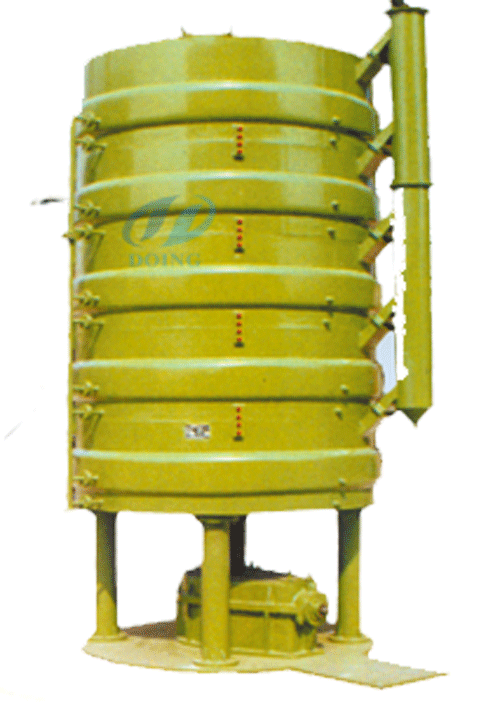

4. Cooking :

Cooking reduces moisture in flakes, which is much easier to press oil out from oil seeds.

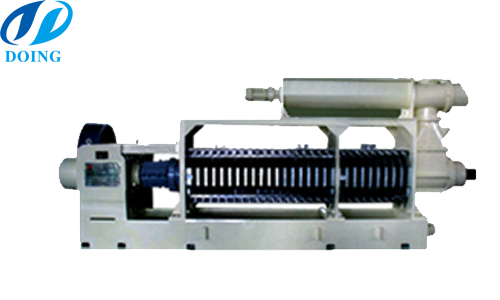

5. Pressing :

The final products of this section is just pressed canola oil and pressed oil cake.

1. Extractor :

In extractor, cake is mixed with solvent evenly while oil is sepearated from other ingredients to mix with solvent.

2. Desolventizer toaster :

After extractor, mixture of oil, cake and solvent is separated to oil mixture(mainly oil), and cake mixture(mainly cake). Cake mixture is heated with steam in desolventizer toaster and with further operation we can get pure cake to be used in animal feed.

3. Stripping tower/ oil stripper :

Oil mixture is heated with steam to get pure oil and solvent is collected to be reused.

|

|